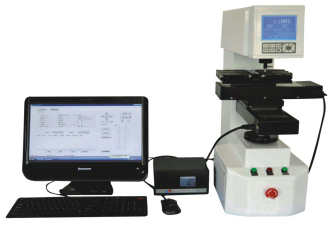

HRS-150 45DX-ZX Semi-Automatic Rockwell Superficial Roc

Product description:

Product Features: ●Automatic testing process, put the sample, press the Start button that was more than the hardness value for each sample. ●Can be multi-point measurement, such as automatic measuring a sample of Jominy end quench curve

●Automatic testing process, put the sample, press the "Start" button that was more than the hardness value for each sample.

●Can be multi-point measurement, such as automatic measuring a sample of Jominy end quench curve

●Samples automatically rise (no height restrictions)

●Automatic initial test force is applied, the main test force is automatically applied

●Automatic measurement of hardness, hardness values of automatic digital display

●Touch-screen interface, easy to operate, in any language version

●Boot, no need to install weights, no installation

●Electric load, closed-loop control

●Accuracy Test force automatic correction, the force increased by one order of magnitude

●Password protection setup parameters; more samples and test information

●Modular design, easy maintenance

●Automatically correct curvature radius; by GB / ASTM hardness automatically converted

●The mean, standard deviation, etc. automatically calculated hardness values, unqualified value automatic alarm, automatic calculations, generate customized inspection reports

Application Fields:

Industrial production, Inspection of product quality on processing technology. Ferrous and nonferrous metals, Hardened steel, tempered steel, annealed steel, hardened steel, sheet of various thicknesses, carbide materials, powder metallurgy materials, hardness and thermal spray coating.

Sheet metal, thin-walled pipe, hardened steel, and small parts of hardness.

Widely used in machinery manufacturing, metallurgy plants, universities, laboratories, etc.

Technical Parameters:

| Product model | HRS-150 45DX-ZX |

| Exchanging scales | Rockwell, Brinell, Vickers |

| Configuration | Z axis rising |

| Samples rise | Automatic |

| Automatic sample rate rise | 3mm/s |

| Preliminary test force loaded | Automatic |

| Main test force loaded | Automatic |

| Automatic sample rate rise | 3mm/s |

| X direction moving precision | 0.003mm |

| Moving distance on X direction | 100mm |

| Statistical analysis of hardness | Yes |

| Hardness testing database query | Yes |

| Customized inspection reports | Automatic |

| Dwell time | 0-60s |

| Initial load of Rockwell | 10kgf (98N) |

| Total load of Rockwell | 60kgf (588.4N) 100kgf (980.7N) 150kgf (1471N) |

| Initial load of Superficial Rockwell | 3kgf (29.4N) |

| Total load of Superficial Rockwell | 15kgf (147.1N) 30kgf (294.2N) 45kgf (441.3N) |

| Load value error | Less than 0.5% |

| Hardness testing range |

HRA: 20-96 HRB: 20-100 HRC: 20-70 HRD: 40-77 HRE: 70-100 HRF: 60-100 HRG: 30-94 HRH: 80-100 HRK: 40-100 HRL: 50-115 HRM: 50-115 HRR: 50-115 |

| Testing rage of Superficial Rockwell |

HR15N: 70-94; HR30N: 42-86; HR45N: 20-77; HR15T: 67-93; HR30T: 29-82; HR45T: 10-72 |

| Hardness measurement accuracy | 0.1 |

| Executive standard | GB/T230.1 GB/T230.2 national standard JJG112 verification regulation |

| Max Height of Sample | 220mm |

| Distance of Indenter to outer wall | 200mm |

| Hardness reading | LCD display |

| Data output | USB flash disk |

| Power supply | AC220V |

| Net weight | About 70kg |

.jpg)

Jinan Hensgrand Instrument Co., Ltd.

Jinan Hensgrand Instrument Co., Ltd. +86-15910081986

+86-15910081986  +86-15910081986

+86-15910081986

4915,West jingshi Road,jinan 250012,PR CHINA.

4915,West jingshi Road,jinan 250012,PR CHINA.