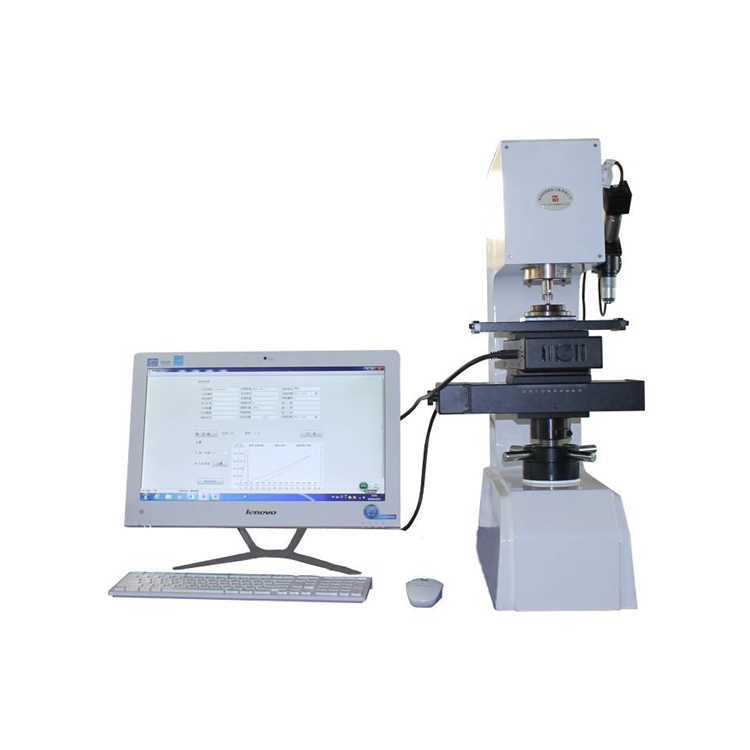

HBRVI-150Z-XYA

Product description:

HBRVI-150-XYA Fully Automatic Instrumentation Blowi Hardness Tester product description: The HBRVI-150-XYA fully automatic instrumented Browsing hardness tester is the only fully automatic Brinell, full Rockwell, Vickers, and instrumented h

product description:

The HBRVI-150-XYA fully automatic instrumented Browsing hardness tester is the only fully automatic Brinell, full Rockwell, Vickers, and instrumented hardness tester in the world.

The hardness tester has a large loading force range, and the loading speed is adjustable in sections.

Automatic multi-point, multi-sample automatic measurement.

Performance characteristics:

1. Automatic measurement of loading force-loading and unloading curve of indentation depth

2. Automatically measure the load and displacement curve with time

3. Maximum force value: 150 kg

4. The loading and unloading speed is set in nine different speeds during the loading and unloading process

5. Select the measurement area under the microscope, and then measure the hardness curve of the area

6. Suitable for different indenters (diamond cone Rockwell indenter, spherical indenter, diamond quadrangular pyramid Vickers indenter, etc.), and can also measure load-displacement curves

7. Measure the hardness of all Rockwell scales on Rockwell and surface Rockwell

8. Measure all Vickers hardness values above 2Kg

9. Measure all Brinell hardness values of 5-125Kg

10. Multi-point, multi-sample measurement, batch measurement, such as automatic measurement of the end-quenching curve of six end-quenched samples (optional);

11. Automatically apply the initial test force and automatically apply the main test force;

12. The hardness value is calibrated separately for low, medium and high hardness;

13. Automatic conversion of hardness according to national standard/ASTM

14. Automatic alarm for unqualified value;

15. Automatic calculation of the average value and standard deviation of the hardness value;

16. Hardness testing data is always maintained and database query is performed;

17. Automatically generate customized inspection reports

18. Martens hardness can be measured (optional)

Measurement result measurement process curve:

| Features | Brinell, full Rockwell, Vickers, instrumented hardness tester |

| Brinell | |

| Force value (Kgf) | 5, 6.25, 10, 15.625, 25, 30, 31.25, 62.5, |

| 100, 125 | |

| Vickers | |

| Force value (Kgf) | 3.0, 5.0, 10, 20, 30, 50, 100, 120 |

| Lowe | |

| Rockwell initial test force | 10kgf(98.07N) |

| Rockwell test force | 60kgf(588N) 100kgf(980N) 150kgf(1471N) |

| Initial Rockwell test force | 3kgf(29.4N) |

| Surface Rockwell total test force | 15kgf(147.1N), 30kgf(294.2N), 45kgf(441.3N) |

| Rockwell Ruler | HRA, HRB, HRC, HRD, HRE, HRF, HRG, HRH, HRK |

| Surface Rockwell Ruler | HR15N, HR30N, HR45N, HR15T, HR30T, HR45T |

| Apply initial test force | automatic |

| Apply the main test force | automatic |

| Instrumented measurement | |

| Maximum pressure (Kgf) | 150 |

| Minimum pressure (Kgf) | 3 |

| Loading and unloading speed | 9 levels can be set |

| Speed during loading and unloading | 9 levels can be set |

| X/Y/Z movement | |

| Z-axis indenter rises or falls | automatic |

| Sample X/Y direction movement | Automatic movement |

| X/Y direction movement accuracy (mm) | 0.003 |

| X/Y direction moving distance (mm) | 100 |

| measuring | |

| Optical magnification | 2X |

| Hardness value display | automatic |

| Hardness value conversion | automatic |

| Hardness value output | Computer hard drive |

| Hardness statistical analysis | Have |

| Hardness testing database query | Have |

| Customized inspection report | Automatically generated |

| Load-speed curve | automatic |

| Data storage format | EXCEL file |

| other | |

| Dimensions (mm) | 520*240*720 |

| power supply | AC220V |

| Host weight | About 65Kg |

Jinan Hensgrand Instrument Co., Ltd.

Jinan Hensgrand Instrument Co., Ltd. +86-15910081986

+86-15910081986  +86-15910081986

+86-15910081986

4915,West jingshi Road,jinan 250012,PR CHINA.

4915,West jingshi Road,jinan 250012,PR CHINA.